WITH WARREN PARTS SORTERS, YOU HAVE THE RIGHT PART EVERY TIME

Jerhen Industries builds a broad range of Warren designed roll sorting equipment. Designed to operate independently or function as an integral part of a cellular manufacturing application, our roll sorters are easy to use and built for durability. You can chose from portable, all-in-one sorters or fully custom high-speed systems with multiple lanes. With a wide variety of standard and optional features, it’s easy to tailor a roll sorter for your specific needs. For applications that require parts to be sorted by length (or other feature that doesn't work with a roll sorter) we suggest you ask about our vibratory feeder bowls, which are ideally suited for uniquely shaped parts.

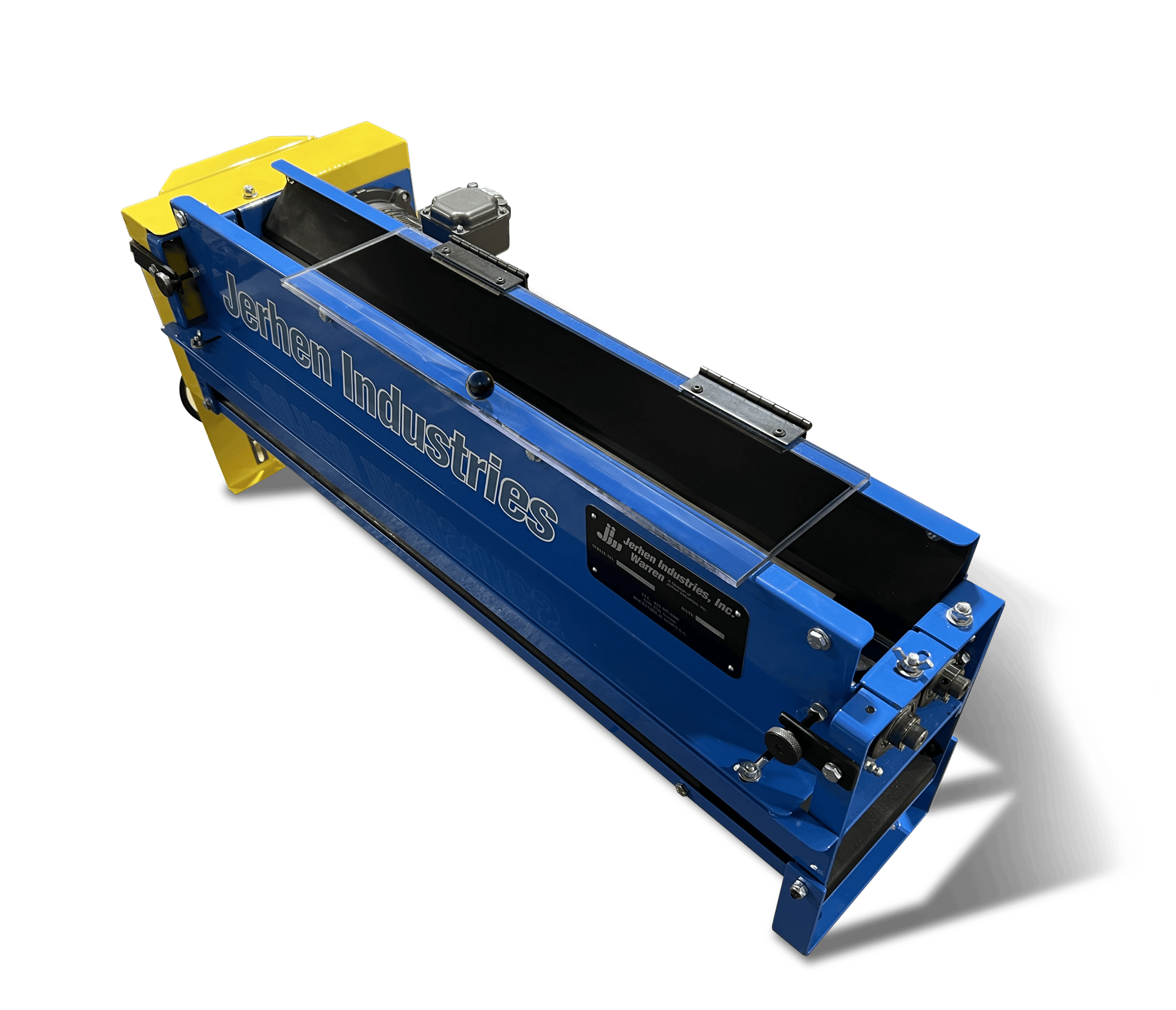

WARREN PORTABLE ROLLER SORTERS

Warren designed portable roller sorters are designed to provide an economical way to sort good or desired parts from mixed batches by major part diameter. These parts sorters use precision ground, hardened steel rollers for maximum durability. Our integral incline adjustment allows the operator to control part throughput to meet the needs of the application.

Designed for quick setup and part changeover, our portable roller sorters have conveniently located thumb screws for easy adjustment of the rollers. The part deflector insures proper part orientation at the loading area, which reduces the chance of parts jamming or the need for constant operator attention. The acceptable parts are discharged from the front chute while the non-conforming parts are discharged through the side chute.

WRS 1-24 AND WRS 1-30 STANDARD & OPTIONAL FEATURES

- Precision ground, hardened steel rollers for longer service life

- 110v motor with single speed controller

- Simple thumb screw roller adjustment for easy set-up

- Adjustable incline to control feed rate

- Compact, all-in-one design for ultimate versatility

- Variable speed controller for easy, infinite feed rate adjustment

- Heavy-duty floor stand with or without casters

- Vibratory feeder bowl or supply hopper for feeding parts

SPECIFICATIONS:

WRS 1-24

- Roller Length: 24"'

- Machine Length: 32"

- Drive Motor (AC, Fixed Speed): 1/4 h.p.

- Electric Requirements: 120 VAC

- Weight: 80 lbs

- Maximum Part Length: 3"

- Maximum Part Diameter: 3/4"

WRS 1-30

- Roller Length: 30"'

- Machine Length: 38"

- Drive Motor (AC, Fixed Speed): 1/4 h.p.

- Electric Requirements: 120 VAC

- Weight: 100 lbs

- Maximum Part Length: 3" (optional 6")

- Maximum Part Diameter: 3/4"

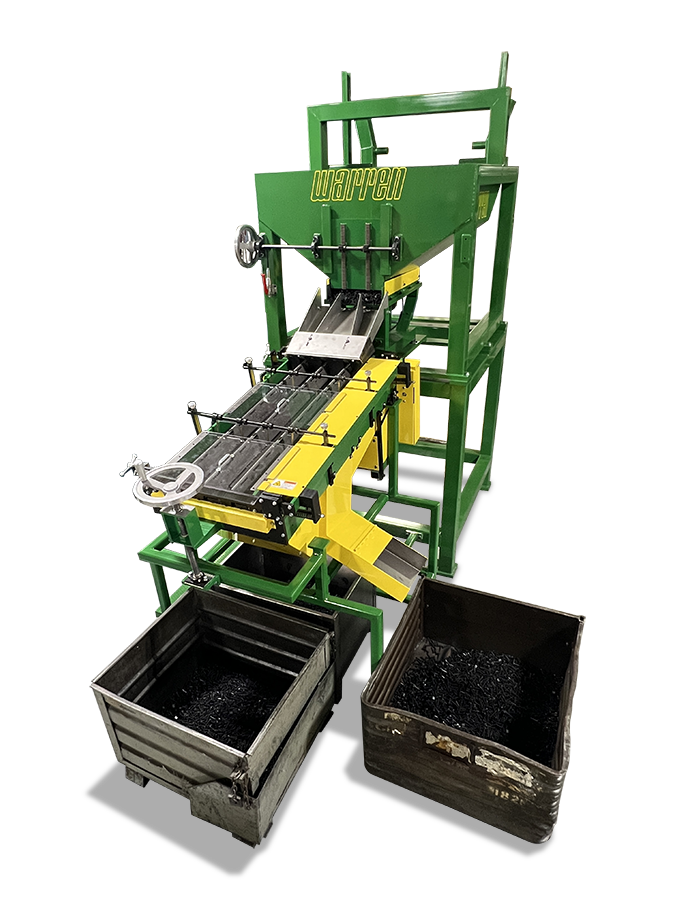

WARREN HIGH-SPEED ROLLER SORTERS

Warren high-speed roller sorters are offered in a number of configurations, including multiple-lanes, to meet your specific requirements. Working with the diameter of acceptable parts our roll sorters can quickly determine pass/fail of a part, acceptable parts from foreign parts or debris, and separate mixed batch parts by size. High-speed roll sorters are ideal for high volume sorting, packaging, and quality control.

Setup and part changeover is accomplished by a simple, single point adjustment. Even with our multi-lane units the rollers are adjusted simultaneously, with a single adjustment knob, making changeover a snap. All of our roll sorters utilize precision ground, hardened steel rollers for accuracy and maximum durability. Variable speed controllers ensure efficient throughput. Our multiple discharge chutes can be configured to your specific needs.

HIGH SPEED SORTERS STANDARD & OPTIONAL FEATURES

- Precision ground, hardened steel rollers for longer service life

- 120 VAC motor with single speed controller

- Exclusive Warren adjustment system for quick and easy setup and changeover

- Adjustable incline to control sort rate

- Wide selection of models and configurations to fit a variety of applications

- Variable speed drives for infinite throughput adjustment

- Packaging-by-weight station and/or conveyor can be added for automated systems.

- Part loaders, feed hoppers and tub dumpers can be incorporated to improve efficiency.