WARREN PARTS WASHERS: A COMPLETE CLEANING SYSTEM

Warren designed, Jerhen produced washers are a great option for cleaning parts without using harsh chemicals. Our jam-free design uses an exclusive drum-style auger that moves the parts past multiple high-pressure sprayers. This highly efficient design incorporates a dual disk oil separator that requires less downtime for solution change. The operator adjustable settings for washer speed and dryer temperature deliver outstanding results every time. Chose between the WW-500 for parts up to 3" or the WW-750 for parts up to 5" in length.

Warren parts washers are available with a wide range of standard and optional features to assure their compatibility with your washing requirements. For high volume production two machines can run in tandem, the first dedicated to wash and the second for rinse and drying.

These washers can also be adapted for special applications such as spraying wax-rust inhibitors.

WARREN MINI WASHER

STANDARD FEATURES FOR THE WW-500 AND THE WW-750 MINI WASHERS

- Patented jam-free, auger-style conveyor system

- Variable speed drum control (0-16 RPM)

- Oil separation system for keeping wash solution clean

- Thermostatically-controlled wash solution heater

- Oven-style dryer controlled by an adjustable thermostat

- Easily accessible operator control panel

AVAILABLE OPTIONS

- Dual oil skimmer (for the WW-500)

- Special/custom augers

- Tandem units for the rinse cycle

- A support table

- 2-cubic-foot hopper

- Other custom features are available to meet your specific needs

Warren auger-style mini washers help make the process of parts cleaning more time-efficient and cost-effective. Warren mini washers can function either as a "stand-alone" parts washer or in combination with a manufacturing cell, providing washed and dried parts without any additional material handling.

Warren mini washers utilize a patented, jam-free auger-style conveyor to move the parts through the wash chamber, where a pressure-sprayed liquid soap solution removes the residue. Warren's state-of-the-art oil separation system helps to maintain a cleaner wash solution without the use of CFC-based solvents, allowing you to comply with current environmental regulations. The temperature of the wash solution is maintained at approximately 125ºF by a thermostatically-controlled heating unit.

After the parts have been thoroughly washed, the drum-style auger moves them to an oven-style drying chamber before discharge. The drying heater is controlled by an adjustable thermostat that can be easily regulated by the operator. Both the auger and the thermostat are adjustable to assure proper cleaning and drying.

WARREN MINI WASHER MODELS

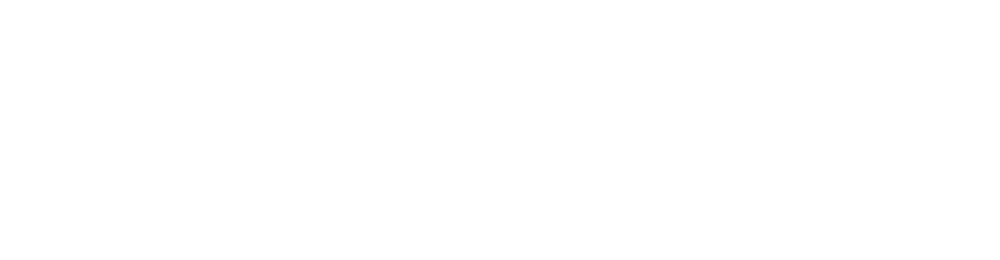

WW-500

Max. Part Length: 3”

Tank Capacity: 25 or 50 Gallons

Oil Separation: Single Disk

Drive Motor: Vari-Speed

Wash Pump: 1/4 HP

Nozzles: 5

Weight: 350 lbs.

Rotation: Vari-Speed 0-16 RPM

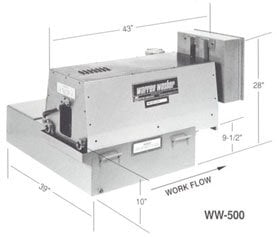

WW-750

Max. Part Length: 5”

Tank Capacity: 60 Gallons

Oil Separation: Dual Disk

Drive Motor: Vari-Speed

Wash Pump: 1/4 HP

Nozzles: 7

Weight: 450 lbs.

Rotation: Vari-Speed 0-16 RPM

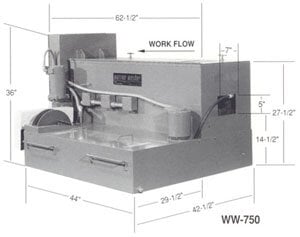

WARREN DUAL WASHER

The Warren dual washer will help make the process of washing, rinsing, and drying much easier. This alternative cleaning system accomplishes the rinse cycle through the use of an additional tank attached under the existing washer. The pressure pump within this tank returns water to the washer’s drum in order to rinse the parts between the washing and drying phases.

STANDARD FEATURES FOR THE DUAL WASHER

- Jam-free, auger-style conveyor system

- Oil separation system to clean wash solution

- Fifty-gallon wash reservoir

- Carbon steel drum with 3/32" perforations

- Wash solution heater, which maintains a 125°F wash temperature

- Variable speed drive motor

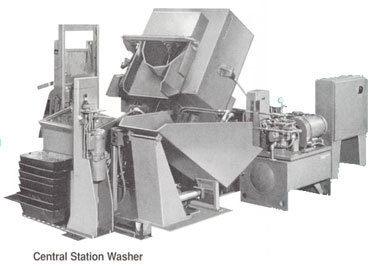

WARREN CENTRAL STATION WASHER

The Warren central station washer is a multifunctional cleaning system that can also be used for the tumbling, polishing, and/or deburring of larger volumes of parts. The central station washer has been designed to minimize floor space requirements and is ideally suited for large-batch, high-volume applications.

STANDARD FEATURES FOR THE CENTRAL STATION PARTS WASHER

- Cleaning barrel with a 4 cu capacity, constructed with a dodecagon shape for optimal tumbling and polishing action during the cleaning cycle (can be used for deburring by turning off the cleaning fluid pump

- Two high-speed pumps

- Two electric heaters capable of reaching and maintaining a 180-200°F wash temperature

- Adjustable wash and dry timers, which allow the operator to select the proper cycle time for each operation

WARREN TUB WASHER

After your parts have been thoroughly cleaned by either a Warren mini washer or a Warren central station washer, you want to make sure that the tub in which the parts were stored is washed as well.

The WTW-20 tub washer has the capacity to clean any standard, palletized side open parts tub. The tub washer uses a heated liquid soap solution to remove residual oil and dirt from the tub surface. The WTW-20 tub washer is the quick and efficient way to clean your parts tubs with a normal cycle time of only five minutes.

STANDARD FEATURES FOR THE WARREN TUB WASHER

- Skimmers to separate the oil from the soap solution

- An automatic gate lift

- TA counter-weighted hood for easier opening and closing