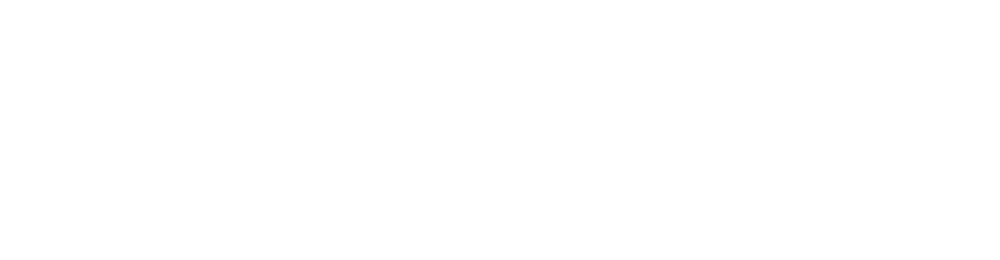

JERHEN INDUSTRIES VIBRATORY FEEDER BOWLS:

hIGHLY RELIABLE, EXPERTLY DESIGNED

Jerhen offers one of the industry's most complete line of standard and custom-engineered vibratory feeder bowls. Designed to your specifications and fabricated to exceed your expectations. Our standard sizes begin at 6" diameter and go up to 42" diameter.

WHAT IS A VIBRATORY FEEDER BOWL?

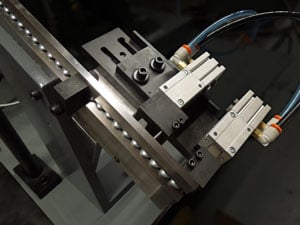

A vibratory feeder bowl is used to sort, orientate, and feed individual parts for assembly on industrial production lines. It consists of a drive base, the bowl, spiral track inside the bowl, and exterior tooling. The vibration of the bowl moves and orientates the parts as they travel along the track and through the tooling. When the parts reach the discharge they are perfectly positioned for the next process. This technology provides an elegant, cost-effective alternative to manual sorting and placing parts within an assembly process.

WHY DO SO MANY CHOSE JERHEN AS A PARTNER?

Since the beginning we have committed ourselves to delivering the longest lasting and most reliable feeder systems money can buy. We believe there is only one way to build a feeder bowl: The best way.

- 11ga. stainless steel bowl and tooling

- Additional gussets for smoother operation and longevity

- Full ring mounts for heavy-duty bowls

- Replaceable, hardened A-2 steel tooling for high-wear areas

40 YEARS OF FEEDING GLOBAL INDUSTRY

STANDARD & OPTIONAL FEATURES

- Stainless steel construction

- Polished or sandblast finish

- Sizes range from 6" to 42" diameter

- 120v or 240v

- Dual coil drive for bowls up to 27" diameter

- Discharge height to your specification

- Choice of clockwise or counterclockwise rotation

- Variable speed controller

- Multi-lane discharge

- Quick dump

- Tooling to feed different sizes

- Inline feeder

- Storage hopper/Pre-feeder

- Heavy-duty base

- Photoelectric shut-off sensor

- Pharmaceutical grade finishing